|

|

|

Below are a few common problems that pop up during an EFI installation

|

|

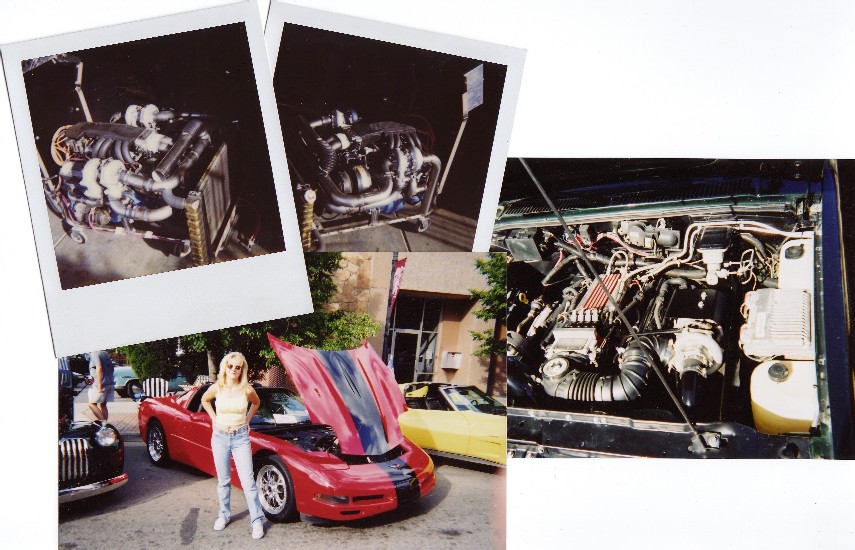

Significant Others

|

| |

OK if you have one then you either know how to balance your life or eventually you won't need to. We can't help you or give advice on this one. You may want to read some books like Love Languages or ????? If you don’t you may loose your little red sports car.

|

|

Crank Power

|

| |

The Ignition on wire is not connected to a good power source during cranking as well as key on. Engine will crank but won't start or catches right when the key is turned back from the crank position.

|

|

Old New Battery

|

| |

Low battery voltage due to an old battery, let's face it the battery is always "GOOD" right? If the voltage is measured with a digital VOM and the voltage is below 12.3 volts before you do anything the look out. If it drops below 11.5 volts when cranking there is a function in the ECM that will change the fuel curve based on voltage drop. The ECM will stop working just a little below 11 VDC. Get a new battery anytime you are doing a new engine. You just put a bunch of money in it already what's $60. Trust me you'll be happy that you did.

|

|

Charging Issues

|

| |

The charging system has a problem, same as the battery problem, look at what is happening with your voltage for the first couple of drives. 1 wire alternators are cool but when the RPM drops down like a TPI ECM likes, the voltage will more than likely drop. This is bad see above. Probably not going to cause major problems just be aware when idling for long periods that you are not charging the battery unless you have a higher voltage coming out of the alternator than the battery has sitting still. The idle quality will be erratic if this happens, up and down because the ECM sees low voltage and re-adjusts the fuel, then engine runs faster and voltage comes up and ECM re-adjusts again, and again, and again.

|

|

Fuel Pump Mounting

|

| |

Fuel Pump mounting on the outside of tank. If you decide to use a fuel pump that is mounted on the outside of the fuel tank, make sure of 3 things. 1 The pump is mounted as low as safely possible so that the fuel will gravity feed to the pump. Most pumps are designed to push rather than pull fuel. 2 have a BIG high flow filter before the pump so that any debris or trash can get caught before it is circulated through your fuel system. 3 the pump needs to be mounted as close to the fuel tank as safely possible, remember the pump is a pusher not a puller.

|

|

Fuel Pump Voltage

|

| |

Low voltage to the pump can cause a great deal of intermittent problems like low fuel pressure, pump failure and vapor locking. The pump needs 11.5 volts under load to run right.

|

|

BIG Cams

|

| |

This happens mostly from the older more experienced car people. Big snotty idle cams that sound great. The manufacturer description states "Rough idle". Guess what? The ECM and the EPROM have to be able to work with the characteristics of the cam to make the system work. The EPROM (erasable programmable read only memory) have the function of taking the data from the sensors and then they use math tables and known constant information to produce the correct injector pulse and timing advance for what the engine is doing at that millisecond. Some thing as seemingly minor as less vacuum at an idle has very major consequences. The car can drive absolutely fantastic and scream down the road but good luck getting the car to come to a stop without idle issues or most likely just shutting down. The center line angle or lobe separation combined with total duration is what will allow the system to have enough vacuum at an idle or not. This will allow the MAP sensor to provide the right signal for idle parameters within the EPROM programming. Call Competition Cams and get as much information as you can about the cam that you need for what you are doing. Stay away from any cam that is less than 112 degrees of lobe separation. We have tuned some as low as 108 but the countless hours of programming will take your project completely out of budget. Buy a cam that has the term computer compatable in it's desription.

|

|

MAP Connection

|

| |

When the vacuum line is connected to the MAP sensor, the hose needs to go from the back of the TPI upper plenum passenger side rear, then directly to the sensor. Do not "T" into that line, otherwise a vacuum mismatch is probable.

|

|

Fuel Presure

|

| |

TPI fuel pressure should be 37-45 psig. 37 at an idle then at wide open throttle under load it will go to 45 psig.

|

|

Grounding

|

| |

In order for all of the sensors, relays and other components to work properly, the grounding needs to be complete.

|

|

|